GOLD (Grupo de Óptica de Láminas Delgadas) is a research group affiliated with Instituto de Óptica-CSIC (Madrid, Spain). GOLD is an expert in the development of optical coatings for the far and extreme ultraviolet (FUV-EUV), where wavelength ranges from 12 to 200 nm.

Why are we working in the FUV-EUV? Space instrumentation for observations of the atmosphere, the Sun and the galaxy, but also Nanolithography, Plasma diagnostics, Synchrotron radiation, among others, are disciplines that require handling FUV-EUV radiation and hence they need efficient optical coatings. In contrast to the visible and adjacent optical ranges, where all sorts of successful optical coatings are available, the FUV-EUV typically lacks of efficient coatings. If we succeed in the development of such coatings, many challenges could be attempted.

What are GOLD’s motivations and goals? To excel in the development of coatings that society demands. In the last decades various disciplines are shifting to applications that involve the FUV-EUV, so that the demand for new and efficient coatings has considerably risen. GOLD is collaborating with companies and research centers to provide customized FUV-EUV coating solutions for these applications.

What products are in our catalogue? At present we have developed or are developing various sorts of coatings:

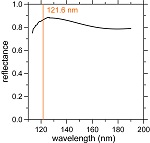

- Broadband mirrors for the FUV and the EUV

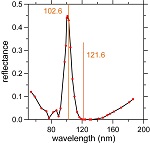

- Narrowband mirrors for challenging wavelengths such as 102.6 nm (Hydrogen Lyman b line)

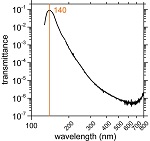

- Transmittance filters with strong rejection of the long wavelengths

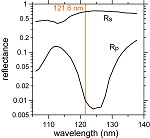

- Efficient polarizers for a wavelength as short as 121.6 nm (Hydrogen Lyman a line)

Our expertise includes a big database of optical constants of materials, the required parameter for multilayer design.

What experimental techniques are available at GOLD?

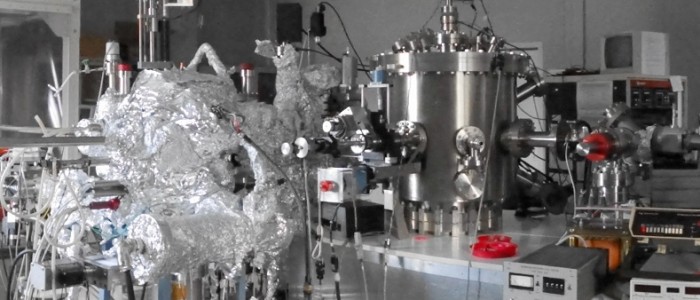

GOLD has deposition chambers mostly based on thermal evaporation, but also ion-beam-sputtering (IBS). The largest chamber, with a 75-cm diameter, is in ISO-6 (class 1,000) clean-room conditions.

GOLD’s main instrument for optical characterization is a reflectometer covering the spectral range of 12.5-200 nm. The reflectometer is connected in vacuum to a deposition system able to deposit multilayer coatings combining evaporation and IBS deposition techniques. This makes it a unique instrument that is able to measure the EUV-FUV optical properties of coatings prepared in situ, i.e., before exposing the coating to the atmosphere. The reflectometer is in an ISO-8 (class 100,000) clean room. This is one of few instruments in the world covering this spectral range which is not installed in a synchrotron.

Techniques such as ellipsometry in the 190-1000 nm and conventional spectrophotometers are also available. Other techniques, such as X-ray diffractometry and atomic-force microscopy, are conveniently accessible in the Madrid area.

What tasks of the coating process can be made at GOLD?

GOLD can carry out all the tasks connected with FUV-EUV coatings:

- Coating design

- Coating deposition

- Coating optical characterization

- Prototype fabrication

How can we contact GOLD?

Contact person: Dr. Juan Larruquert; email: j.larruquert@csic.es, phone: (34)915618806-ext. 330.